CNC milling

processes

Meccanica RC specialises in a wide range of precision machining, including METAL MILLING.

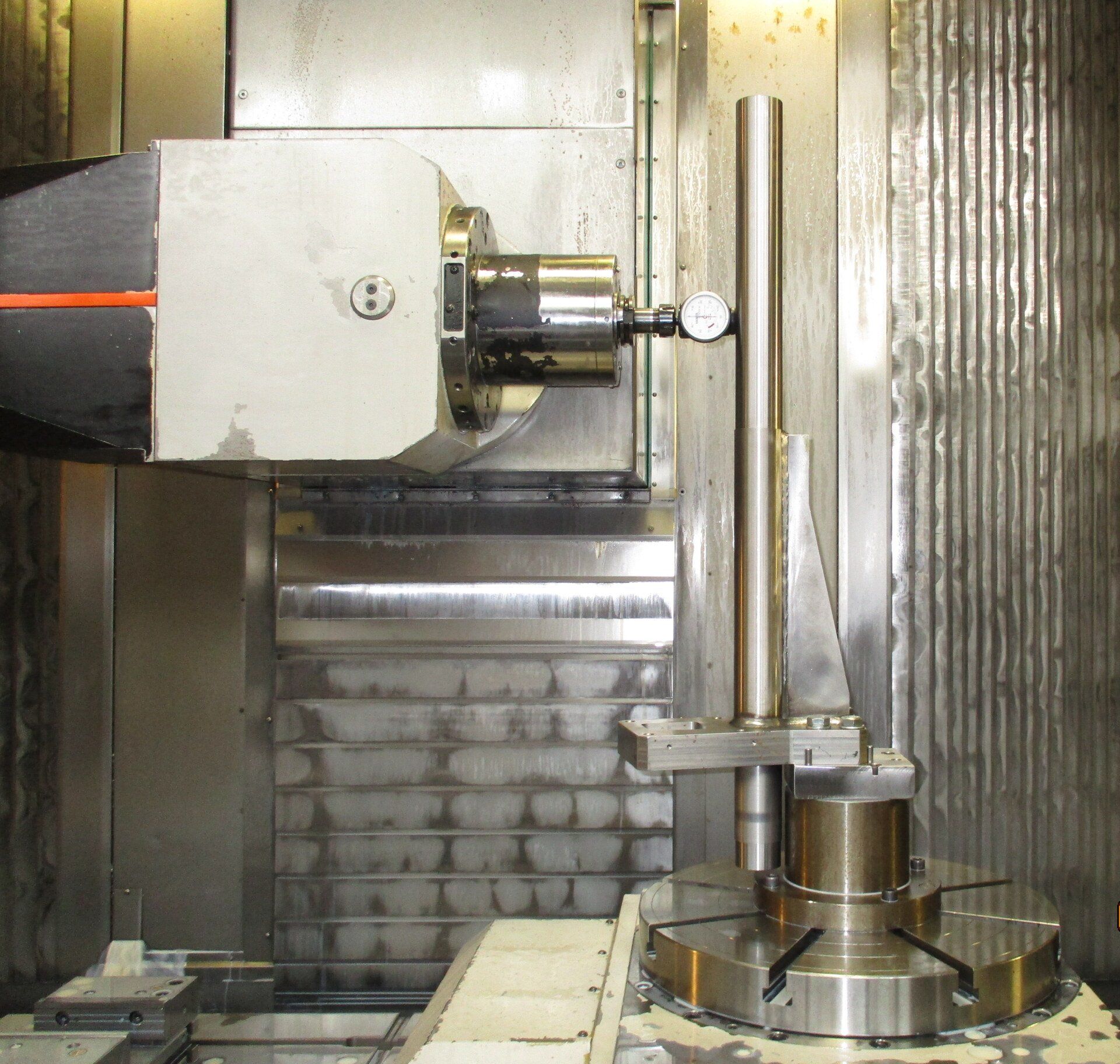

CNC milling machines

Our company has many pieces of high-precision machinery, so that we can make sure that we provide our customers with a very high-quality of service. For CNC numerical control milling, Meccanica RC has around fifteen of the most up-to-date CNC WORKING CENTRES in our workshop in Palazzuolo sul Senio, in the province of Florence, featuring working ranges of up to 3500mm ( X axis) x 2500mm (Y axis) x 1300mm (Z axis), with the possibility of performing continuous 5-axis machining.

Two MULTITASKING MAZAK INTEGREX I 200 S machining centres with 5 continuous axes and counter spindle have also been put into production.

All working CNC machines are always manned by staff, who are there exclusively to make sure that everything is carry out properly as well as checking the product sizes that are being manufactured. The department heads will supervise each stage of the production cycle, and we have other qualified staff members that will carry out some necessary and key operations.

Computer-based workpiece detection in the milling process

In the field of CNC milling, computer-based workpiece detection for each stage and phase of work is very important. By cost centre monitoring within the work cycle that always follow design specifications, our company can ensure continuous checks of the production progress. We can also immediately track the finished processes or those still in progress.

If you would like more information, or for a personalised quote regarding CNC milling and other processes, simply contact us by:

telephone: +39 055 8046658

fax: +39 055 8046069

email: info@meccanicarc.it.

or you can click here to visit our Contact us page section, where you can fill out our form to get in touch with a manager.